Products Description

Detailed introduction: Custom notebook printing

Custom notebook printing is a service that integrates design, craftsmanship and practicality. It is widely used in corporate gifts, brand promotion, student stationery, personal collections and other scenarios. Its core is to customize the entire process from size, material to craftsmanship details according to the personalized needs of customers, and finally present a notebook that is both functional and unique. The following is a detailed introduction from four aspects: customization process, core elements, common scenarios and precautions:

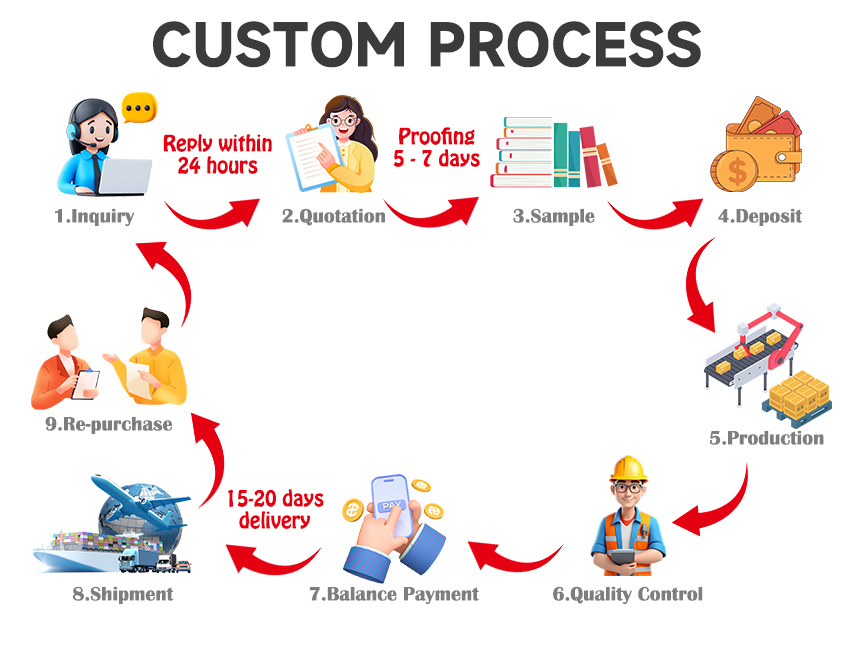

I. The core process of customized notebooks

The process of customized notebooks can be divided into four steps: "demand confirmation → design finalization → production → acceptance and delivery". Each link is closely connected to ensure that the final product meets expectations:

Demand confirmation

Customers need to clarify the core needs, including:

Purpose (such as business gifts, meeting minutes, student notes, etc.);

Specifications (size, number of pages, inner page layout);

Budget (affects material selection and process complexity);

Quantity (the minimum order quantity is usually 50-100 books, and the larger the batch, the lower the unit price);

Delivery cycle (normal 10-15 days, expedited can be compressed to 5-7 days).

Design finalization

The customer provides design materials (such as LOGO, pattern, text), or the printing factory/design company assists in completing the design. The design must include:

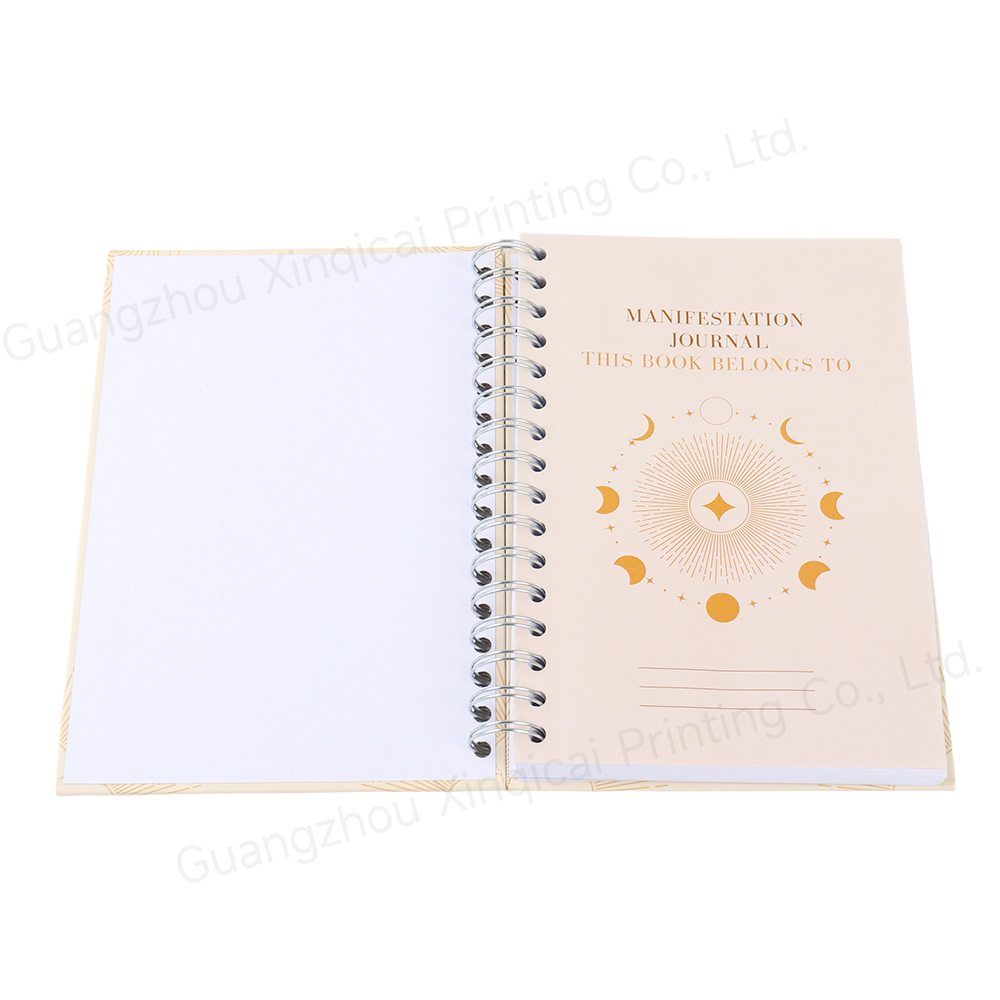

Cover (pattern, text, brand logo);

Inner pages (whether to print grids, horizontal lines, logos, or customize blank pages, schedules, etc.);

Supplementary materials (such as title pages, waist seals, stickers and other additional designs).

The design draft must be confirmed by the customer and converted into a printing file (usually in PDF format, with a resolution of 300dpi or above).

Production

Enter the printing stage, including:

Material selection and cutting (cutting the cover and inner page paper according to the design);

Printing (the cover is printed in color, and the inner pages are mostly single-color or two-color);

Binding (select the binding method according to needs, such as glue binding, saddle stitching, loose-leaf, etc.);

Post-processing (such as lamination, hot stamping, UV, etc., to enhance the texture).

Acceptance and delivery

The printing factory provides samples (or batch sampling), and the customer checks the printing clarity, color reproduction, binding firmness, etc. After confirmation, batch delivery (supports logistics distribution or door-to-door pickup).

II. The core elements of customized notebooks (customizable details)

The customized details of the notebook directly affect its texture and functionality, mainly including the following elements:

1. Size specifications

Common sizes need to be selected according to the purpose, and can also be fully customized:

Portable: pocket size (such as 10cm×15cm), suitable for carrying;

Regular type: A5 (14.8cm×21cm), B5 (17.6cm×25cm), taking into account both writing and portability;

Large size: A4 (21cm×29.7cm), suitable for drawing, meeting minutes, etc.;

Special size: such as square (18cm×18cm), long strip (suitable for accounting, notes), etc., need to be cut separately.

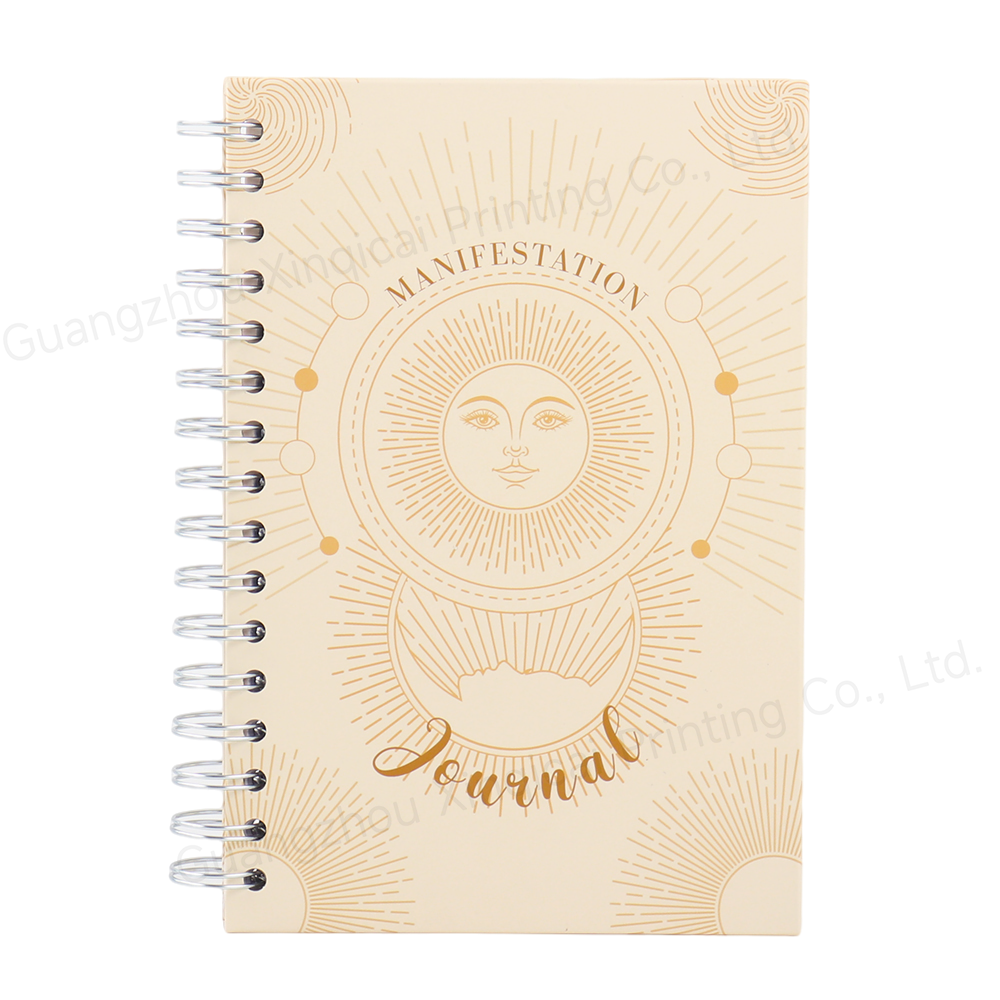

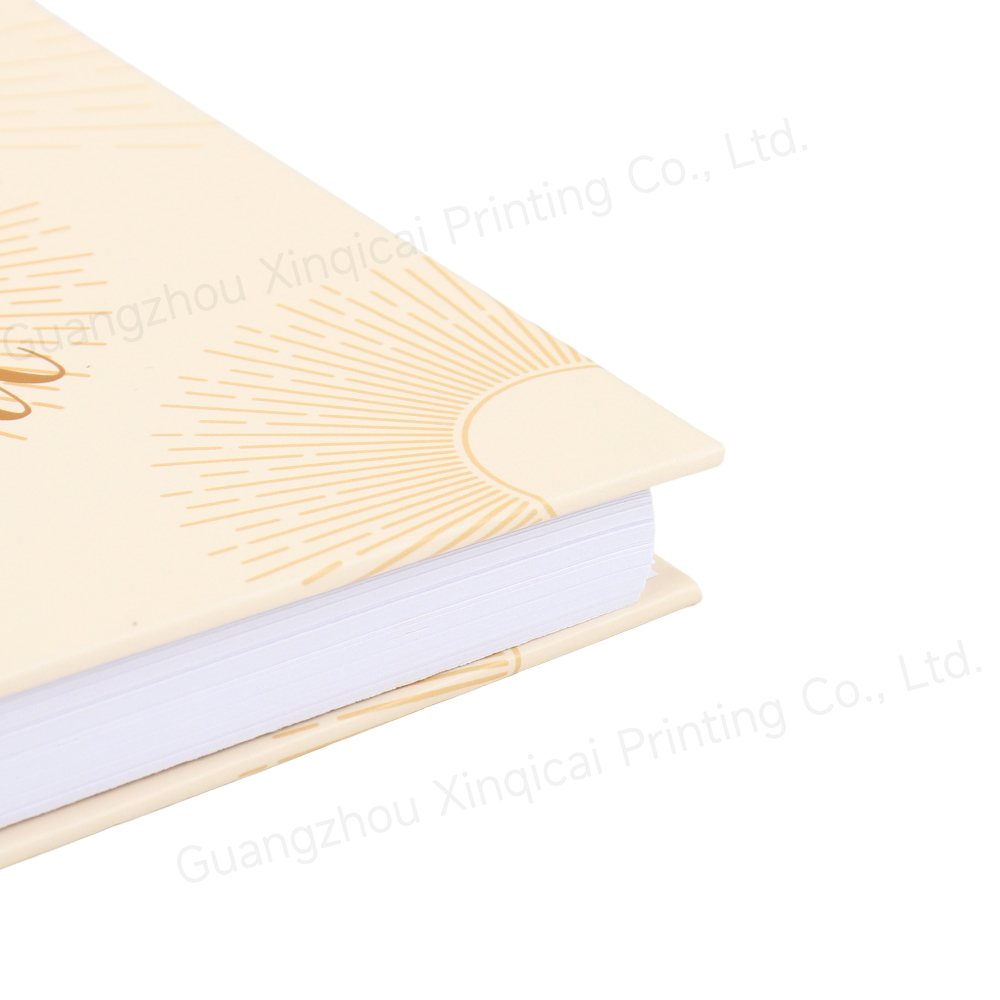

1. Cover material and craftsmanship

The cover is the "face" of the notebook, and the material and craftsmanship determine the visual impact:

Cover material:

Paper: coated paper (smooth and easy to print, suitable for color patterns), kraft paper (retro texture, environmentally friendly and simple), special paper (such as textured paper, cotton paper, with its own texture, enhances the sense of luxury);

Fabric: canvas, linen, leather (PU leather, genuine leather, suitable for high-end business models, soft and durable texture);

Hard cover: cardboard covering (such as hard cover hardcover, crisp and suitable for collection).

Cover craftsmanship (key to improving texture):

Basic craftsmanship: lamination (bright film/matt film, waterproof and scratch-resistant), embossing (textures are pressed by molds, such as leather texture and cloth texture);

Exquisite craftsmanship: hot stamping/hot silver stamping (metal foil hot stamping, highlighting LOGO or text, suitable for business models), UV (local varnish bulge, enhancing three-dimensional sense), embossing/debossing (no ink, the pattern is uneven through pressure, low-key and advanced);

Special craftsmanship: drip molding (the cover is covered with a layer of soft glue, which is soft to the touch), laser engraving (commonly used for leather covers, engraved patterns or text, permanent and clear).

2. Inner page design and material

The inner page is the core functional area of the notebook, and it is necessary to take into account both writing experience and practicality:

Inner page material:

Writing paper (70-80g, suitable for daily writing, cost-effective);

Door paper (beige, eye protection, suitable for long-term writing);

Kraft paper (retro style, suitable for hand-painted or creative records);

Special paper (such as sulfuric acid paper and rice paper, suitable for artistic purposes, but the writing experience is poor).

Inner page layout (customized on demand to meet different scenarios):

General type: blank page (suitable for drawing, free record), lined page (conventional writing), grid page (suitable for drawing, tabulation), dot page (taking into account both writing and creativity);

Functional type: schedule (daily/weekly plan, suitable for office), address book, class schedule (for students only), notebook + handbook combination (with monthly calendar, punch-in page, etc.);

Customization: print the company logo, slogan, contact information, or insert company profile, product information, etc. (mostly used for brand promotion).

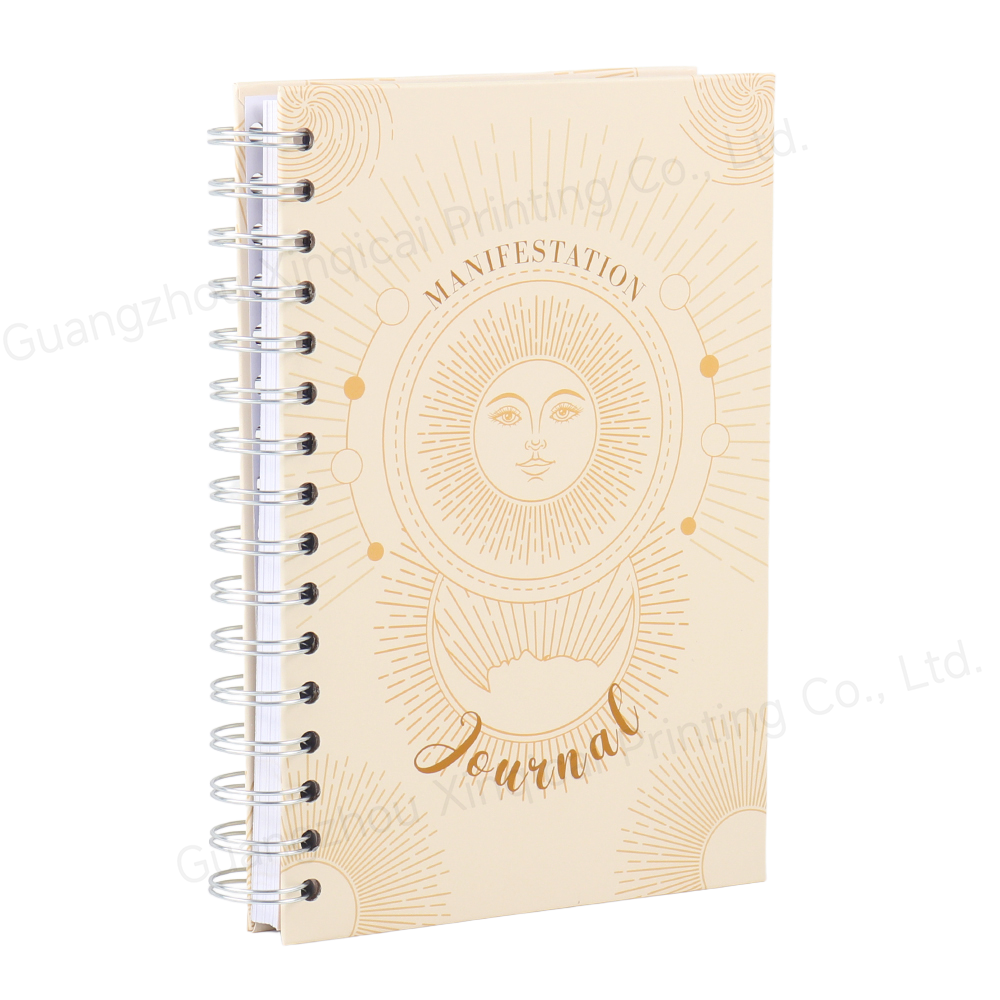

3. Binding method

The binding method affects the opening and closing experience and durability of the notebook. Common types include:

Glue binding: The inner pages are fixed to the cover with glue, which can be laid flat, suitable for thick books (more than 50 pages), and the cost is relatively low;

Saddle stitching: Use wire to nail the fold of the spine, suitable for thin books (less than 30 pages), easy to open and close but easy to loose pages;

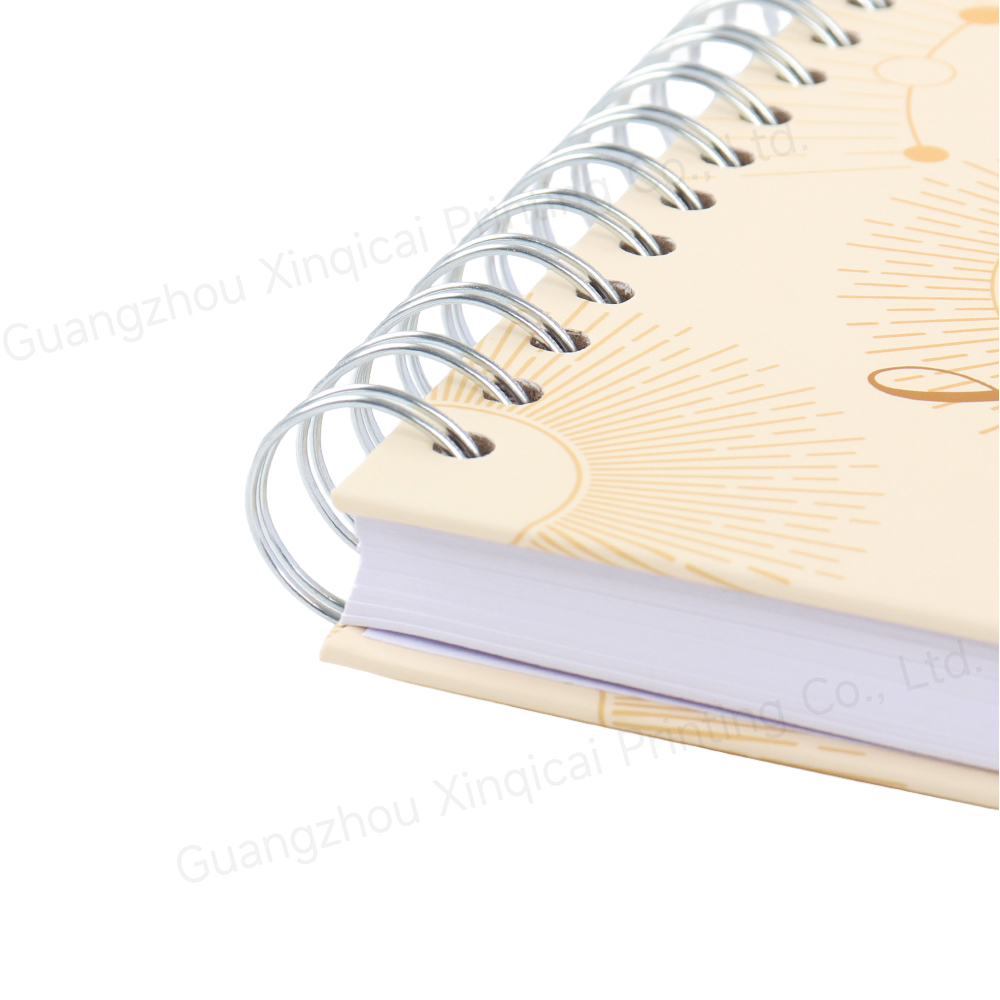

Loose-leaf binding: The inner pages are fixed with loose-leaf rings, the number of pages can be freely increased or decreased, and can be reused with loose-leaf paper, suitable for office and students;

Thread binding: Traditional craftsmanship, the inner pages and the cover are sewn with thread, which is firm and has a retro feel, suitable for high-end customization;

Hardcover with rounded spine: Hard cover, rounded spine, high-end texture, mostly used for commemorative albums or high-end gifts.

4. Accessories and accessories

Use additional accessories to enhance practicality or sense of ceremony:

Title page: Print a welcome message, brand story or signature column on the first page;

Waist cover: A narrow strip of paper outside the cover, which can be printed with slogans or product information to enhance the display effect;

Bookmark rope: Leather or cotton rope, convenient for marking page numbers;

Pen holder: Pen holder designed on the inside or edge of the cover, convenient for carrying pens;

Inner pocket: Add a transparent plastic bag on the inside of the back cover to store business cards, notes, etc.

5. Common application scenarios of customized notebooks

Customized notebooks have a wide range of scenarios, and their core value lies in "personalized expression" and "functional adaptation":

Corporate gifts: Print the company's LOGO and slogan as a gift to customers and employee benefits to convey the brand image;

Conference/activity peripherals: Customized notebooks are used as souvenirs in large-scale conferences, exhibitions, and campus activities to enhance the quality of the event;

Student stationery: Schools and training institutions customize notebooks with school badges and school mottos for daily teaching or graduation commemorations;

Personal collection/cultural creation: Designers and artists customize personal IP notebooks, or sell them as cultural creation products;

Public welfare/commemoration: used for public welfare activities (such as environmental protection theme notebooks), anniversary commemorations (printed with time and events), etc.

III. Precautions for custom notebooks

Cost control: Material and craftsmanship are the core factors affecting the price (such as the cost of leather cover + hot stamping is much higher than that of kraft paper binding), and it is necessary to balance texture and practicality within the budget;

Color restoration: The printed color may be slightly different from the electronic design draft (affected by the paper material and ink batch), and it is recommended to proofread and confirm the color first;

Copyright issues: Customers need to ensure that the design materials (patterns, texts) have no copyright disputes to avoid infringement;

Minimum order quantity and cycle: Small batch customization (such as 10-50 books) has a higher unit price, and some processes (such as hot stamping) may not support small batches; urgent orders need to communicate with the printing factory in advance and reserve sufficient time;

Practicality first: Excessive pursuit of craftsmanship may affect use (such as the cover is too thick and difficult to write), and it is necessary to balance beauty and function in combination with the purpose.

In short, the core of custom notebooks is "design on demand", and every detail from size to craftsmanship can be adjusted according to needs, and finally achieve the triple value of "function + appearance + brand expression". Choosing a regular printing factory (checking cases and proofing capabilities) and clearly communicating needs are the key to ensuring the customization effect.